Sustainable Meat Packaging: Innovations that Reduce Food Waste

In today’s world, sustainability is more important than ever, especially in the food industry. One of the key factors in achieving sustainability in the meat industry is extending the shelf life of meat products. The longer meat can be preserved in packaging, the less meat waste occurs. At Greenflex, a range of innovative packaging solutions has been developed to meet this goal, all while contributing to a more sustainable future.

Plastic-free nets: Biodegradable and Environmentally Friendly

Greenflex is proactively responding to the growing demand for environmentally friendly solutions. Plastic-free netting is a prime example. These nets are made of cotton or other natural fibers, which means they are completely plastic-free. This sustainable choice is a step towards a more sustainable future of meat packaging while reducing the amount of plastic packaging material. Moreover, cotton naturally degrades over time, making it both biodegradable and compostable. This is yet another way the nets help reduce waste.

Benefits of Plastic-Free Nets:

- Environmentally Friendly: These nets are made from biodegradable natural fibers, meaning they don’t contribute to the persistent plastic waste problem and degrade naturally in time.

- Consumer Appeal: As consumers increasingly seek out sustainable products, these nets cater to that demand and can enhance brand loyalty. Furthermore, as it is a natural product, a more natural and authentic look is given to meat and seafood. An example can be seen below.

Patterned Process Net: More Meat, Less Waste and Biodegradable

One of Greenflex’s most innovative products is the patterned process net, specifically designed to peel off easily after cooking meat products, leaving no meat behind. This innovative design plays a crucial role in reducing waste by ensuring that no valuable meat sticks to the net. In addition, it is also available in a fully biodegradable, plastic-free version, which is groundbreaking and something we at Greenflex are very proud of. Lastly, the aesthetic quality of the meat is preserved, making it more appealing to consumers and ensuring less disregard, as can be seen in the image below.

Stockinette: Optimal preservation of carcasses

Another key innovation from Greenflex is the stockinette, a close-fitting net that helps maintain carcasses in perfect condition. By preventing spoilage, the stockinette significantly reduces meat waste during the storage and transportation of meat products. This solution is particularly valuable for large-scale meat processing operations where the preservation of carcasses is essential to minimize waste and ensure food safety.

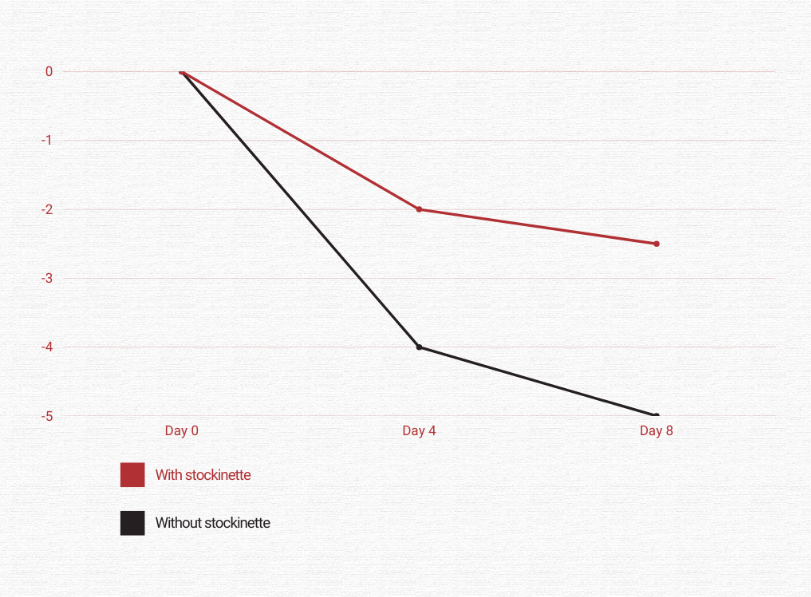

Furthermore, a stockinettes are a sustainable solution for meat preservation due to its ability to significantly reduce weight loss during storage, which directly translates to less food waste. By preventing the meat from drying out and drastically reducing water evaporation, the stockinette minimizes the loss of valuable product. For instance, it was found that the stockinette decreased weight loss by over 3 percent by day 8, with a reduction of 1.09 percent by day 4 and 3.16 percent by day 8. Additionally, its positive impact on reducing drip loss or purge further enhances the preservation of meat quality, ensuring that more of the product remains usable and less is discarded. This not only enhances food quality by preserving resources but also supports a more sustainable food supply chain by maximizing the yield of each carcass.

Latex-free Nets: Reducing the Carbon Footprint

Greenflex also offers latex-free nets, which reduce environmental impact by eliminating the need for natural latex tapping. In alignment with the European Green Deal, these nets are made from raw materials sourced within Europe, further reducing their carbon footprint compared to traditional packaging, while the sustainability goals of the food industry are being reached.

Extrusion nets: Maximum Protection during Storage

Extrusion nets from Greenflex provide optimal protection for meat during storage. These durable and secure packaging for meat ensure that meat remains in good condition for longer periods, which directly contributes to reducing meat waste. The strong construction of extrusion nets minimizes the risk of damage during transportation and storage and therefore preserves product quality.

Cardboard Packaging: Less Carbon and More Recycling

According to the UN, 17 per cent of all food ends up in consumers’ bins. And food waste accounts for 10 per cent of the world’s CO2 emissions. That is why it is important to combat food waste. For example, by extending the shelf life of your food product. At Greenflex, we provide an extensive portfolio of cardboard packaging to pack your fresh meat sustainably and obtain the same or a higher shelf life, reducing plastic by 80-90%. The cardboard is FSC-certified or recycled. Additionally, the cardboard is made out of wood from European forests, contributing to the fact that less CO2 is released during the production process compared to traditional packaging. Finally, our cardboard packaging is 100% recyclable, ensuring circularity. Discover our range of products at our website now.

Conclusion

Greenflex offers a range of innovative packaging solutions that not only extend the shelf life of meat products but also prevent spoilage, which reduces food waste significantly all over the world. From plastic-free nets to latex-free and extrusion nets, these packaging solutions support eco-friendly practices. By choosing these sustainable packaging solutions, you contribute to a more sustainable future and reduce your impact on the environment.

Invest with Greenflex in the future of your meat products today and together we take a stand against meat waste!